Manufacturing and production-driven companies rely heavily on raw material purchasing accounting to play a critical role in controlling costs, maintaining production continuity, and ensuring accurate financial reporting. For any company, raw materials represent one of the largest cost components in manufacturing operations, and even small inaccuracies in purchasing, inventory valuation, or accounting entries can quickly lead to margin erosion, stock shortages, or misleading financial statements.

This is why many manufacturers are moving away from spreadsheets and disconnected tools toward integrated ERP systems. Raw material purchasing accounting with Odoo offers a unified, automated approach that connects procurement, inventory management, manufacturing, and accounting in one seamless system, allowing businesses to streamline and manage their operations more effectively. By centralizing data and automating workflows, Odoo enables businesses to manage raw materials efficiently while maintaining full financial transparency.

A comprehensive view of how Odoo ERP supports raw material purchasing accounting is presented through purchase requisitions, supplier management, inventory valuation, BOM integration, and manufacturing cost control. Odoo provides a user-friendly interface that allows businesses to manage all of their manufacturing operations from a single screen or across different teams in real time.

Key Takeaways

- Raw material purchasing accounting is critical for manufacturing profitability

- Disconnected systems create errors and inefficiencies

- Odoo ERP integrates purchasing, inventory, manufacturing, and accounting

- Automated accounting entries improve accuracy and compliance

- Real-time data enables better cost control and production planning

- Odoo supports continuous improvement in supplier relationships, quality control, and operational efficiency

Key Takeaways

Understanding Raw Material Purchasing Accounting

Challenges in Traditional Purchasing and Accounting Processes

Odoo ERP as an Integrated Purchasing and Accounting System

Setting Up Odoo for Raw Material Purchasing

Purchasing Process in Odoo: From Requisition to Payment

1. Purchase Requisitions and Internal Demand

2. Supplier and Vendor Management

3. Purchase Orders and RFQs

Inventory Management for Raw Materials

Raw Material Purchasing Accounting with Odoo

1. Automatically Generated Accounting Entries

2. Cost Control and Expense Management

3. Landed Costs and Inventory Valuation

Integration with Manufacturing and BOM Setup

Material Tracking, Quality, and Compliance

Accounting and Reporting Benefits

Business Benefits of Using Odoo for Raw Material Purchasing Accounting

Conclusion

FAQs

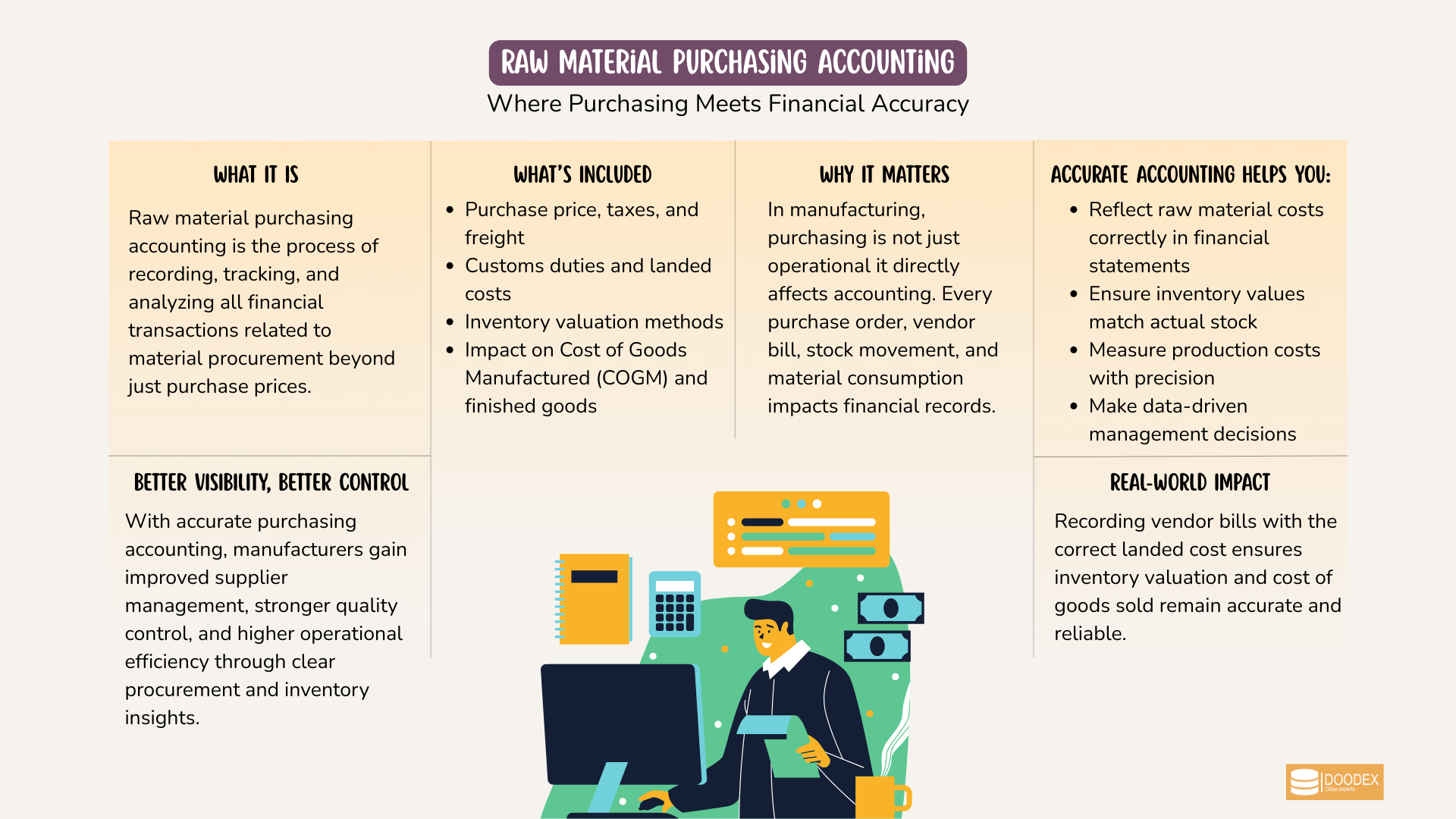

Understanding Raw Material Purchasing Accounting

Raw material purchasing accounting in manufacturing

Raw material purchasing accounting refers to the process of recording, tracking, and analyzing all financial transactions related to the procurement of materials used in production. This includes not only the purchase price but also taxes, freight, customs duties, landed costs, and inventory valuation methods that directly impact cost of goods manufactured and finished goods valuation.

Manufacturing environments treat purchasing as more than an operational activity. Every purchase order, vendor bill, stock movement, and material consumption has accounting implications. Accurate accounting ensures that:

- Raw material costs are correctly reflected in financial statements

- Inventory values match actual stock levels

- Production costs are measured accurately

- Management can make data-driven decisions

Additionally, accurate accounting leads to improvement in supplier relationships, quality control, and operational efficiency by providing better visibility and control over procurement and inventory processes.

For example, recording a vendor bill for raw materials at the correct landed cost ensures that both the inventory value and the cost of goods sold are accurately reflected in the company’s financial statements.

Without a tightly integrated system, companies often struggle with fragmented purchasing processes, inconsistent supplier data, delayed postings, and manual reconciliations.

Challenges in Traditional Purchasing and Accounting Processes

Many businesses still rely on disconnected purchasing, inventory, and accounting tools. These setups create common challenges such as:

- Manual purchase requisitions with limited approval control

- Inconsistent supplier information across systems

- Errors in purchase order pricing and quantity tracking

- Delays in recording vendor bills and accounting entries

- Mismatched stock levels between warehouse and accounting records

- Limited visibility into historical data and cost trends

These issues not only slow down operations but also introduce accounting errors that affect profitability analysis, audits, and compliance. Traditional systems lack the ability to streamline procurement and accounting processes, resulting in ongoing inefficiencies.

Odoo ERP as an Integrated Purchasing and Accounting System

Odoo ERP is designed as a fully integrated business management system, making it ideal for any company seeking to streamline operations. Instead of treating purchasing, inventory, and accounting as separate functions, Odoo connects them within a single database, allowing information to flow automatically between modules.

Key advantages of Odoo ERP include:

- Seamless integration between purchase, inventory, manufacturing, and accounting

- Real-time data synchronization across departments

- Automation of routine business processes

- Strong support for manufacturing and intelligent production planning

Odoo also integrates with other core business functions outside manufacturing, giving companies more streamlined control over the business as a whole.

This integrated architecture is the foundation of effective raw material purchasing accounting with Odoo.

Simplify Purchasing and Accounting

Unify purchasing, inventory, and accounting with an integrated Odoo ERP system

Setting Up Odoo for Raw Material Purchasing

Getting started with raw material purchasing in Odoo begins with configuring the Odoo Purchase module. This powerful tool is designed to help businesses easily manage every aspect of the purchasing process, from supplier selection to order fulfillment. By centralizing supplier information and automating purchase order creation, Odoo Purchase streamlines procurement and ensures you always have the right materials on hand.

To set up, simply install the Odoo Purchase app and connect it with your inventory management system. This integration allows you to monitor stock levels in real time and set up automated replenishment rules, so you never run out of critical raw materials. You can also manage purchase tenders, compare supplier offers, and track the status of every order from a single dashboard.

With Odoo, managing suppliers becomes effortless. The system stores all relevant supplier details, pricing, and historical data, making it easy to negotiate better terms and maintain strong vendor relationships. Automated workflows help you save time and reduce errors, while real-time stock updates ensure your purchasing decisions are always data-driven.

By leveraging the Odoo Purchase module, companies can optimize their procurement process, maintain optimal stock levels, and support seamless integration with other Odoo apps laying the foundation for efficient raw material management and intelligent manufacturing operations.

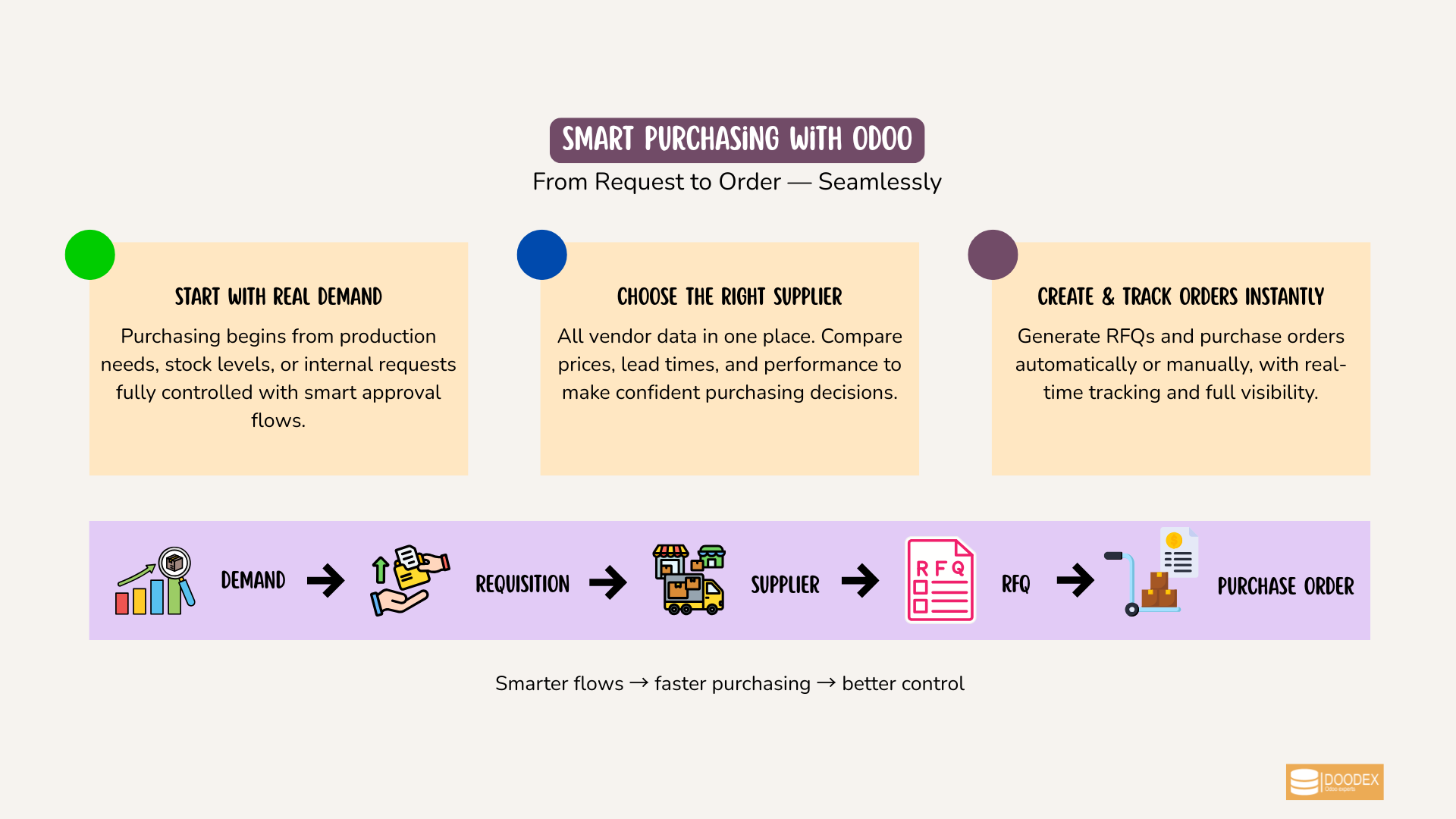

Purchasing Process in Odoo: From Requisition to Payment

Odoo purchasing workflow from request to order

1. Purchase Requisitions and Internal Demand

The purchasing process often begins with internal demand. Employees can initiate purchase requisitions, benefiting from streamlined approval workflows that automate routine processes and allow staff to focus on larger tasks. Odoo allows companies to create purchase requisitions triggered by production planning, minimum stock rules, or manual requests from departments. Approval workflows ensure purchasing control and accountability.

2. Supplier and Vendor Management

Odoo centralizes supplier information in one place. Each vendor record stores pricing history, payment terms, delivery lead times, and past performance. This enables procurement teams to compare suppliers, negotiate better prices, and maintain reliable vendor relationships. Odoo also supports continuous improvement in supplier relationships and procurement efficiency by providing tools to monitor performance and optimize processes over time.

3. Purchase Orders and RFQs

Purchase orders in Odoo can be generated manually or automatically based on inventory rules or production needs. The system supports requests for quotation, vendor comparisons, and multi-level approvals. Once confirmed, purchase orders are tracked in real time, providing full visibility into order status and expected deliveries.

Inventory Management for Raw Materials

When raw materials are received, Odoo automatically updates inventory levels. Inventory management features include:

- Real-time stock level updates

- Multi-warehouse and multi-location support

- Barcode scanners for faster and more accurate receiving

- Lot and serial number tracking for full traceability

- Location-based stock control

- Centralized and user-friendly inventory management settings, making configuration straightforward

- Odoo's MRP system allows manufacturers to track material consumption in real time, providing insights into production efficiency and cost control

These features ensure that inventory data always reflects physical reality, eliminating discrepancies between warehouse operations and accounting records.

Designed for Manufacturing

See how Odoo supports purchasing, inventory, and manufacturing workflows

Raw Material Purchasing Accounting with Odoo

This is where Odoo truly stands out. Purchasing activities automatically generate accounting entries, ensuring accuracy and consistency without manual intervention.

1. Automatically Generated Accounting Entries

When a vendor bill is validated, Odoo automatically posts journal entries to the appropriate accounts. Accrual accounting is supported, allowing expenses to be recognized correctly even before invoices are paid.

This automation reduces errors, saves time, and ensures compliance with accounting standards.

2. Cost Control and Expense Management

Odoo tracks raw material costs at a granular level. Businesses can analyze unit costs, supplier price variations, and budget deviations. Historical data is always available, supporting better forecasting and negotiation strategies.

3. Landed Costs and Inventory Valuation

Landed costs such as freight, insurance, and customs duties can be allocated directly to raw materials. Odoo supports multiple valuation methods, including FIFO and average cost, ensuring accurate inventory valuation and financial reporting.

Integration with Manufacturing and BOM Setup

Raw material purchasing accounting becomes truly powerful when integrated with manufacturing. Odoo connects purchase orders and inventory with BOM setup, production planning, work orders, and work centers, which are key components in manufacturing management for controlling production operations and monitoring shop floor efficiency.

- The Manufacturing app in Odoo allows for the setup of detailed Bills of Materials (BoMs) listing all raw materials and their quantities.

- Bills of Materials define raw material requirements, including multi-level BoMs for accurate cost tracking of nested assemblies and subcomponents.

- Production planning forecasts material demand, using input data from the Master Production Schedule (MPS), Bill of Materials (BoM), and inventory records to determine the materials assembly processes necessary to produce orders on time.

- Work orders and work centers consume materials in real time as raw materials are used to produce finished products, transforming inputs into outputs.

- Odoo provides complete visibility from planned BoM costs to actual production usage.

- Odoo automatically compares actual consumption with theoretical BoM data after production is completed.

- Finished goods costs reflect actual raw material usage and the transformation process from raw materials to finished products.

This integration ensures accurate cost roll-ups from raw materials to finished goods, providing full visibility into production costs.

✨Pro Tip

Automate Cost Accuracy from Purchase to Production

Let Odoo automatically generate accounting entries and connect purchasing with BOMs and manufacturing workflows so raw material costs, landed costs, and actual production usage roll up accurately into finished goods costs.

Automation first → accurate costs → smarter decisions

Material Tracking, Quality, and Compliance

Material tracking, quality, and compliance in manufacturing

Odoo supports end-to-end material tracking, from supplier receipt to finished product delivery. Quality checks can be enforced on incoming materials, with alerts triggered for non-compliance. This improves product quality, supports audits, and enhances supply chain reliability.

Accounting and Reporting Benefits

With all data centralized, Odoo offers powerful reporting tools for purchasing and accounting:

- Inventory valuation reports

- Purchase analysis by supplier and product

- Cost variance reports

- Financial statements updated in real time

These reports enable data-driven decisions and support strategic planning.

Business Benefits of Using Odoo for Raw Material Purchasing Accounting

Implementing raw material purchasing accounting with Odoo delivers measurable business value:

- Increased efficiency through automation

- Streamlined procurement and internal workflows

- Reduced errors in purchasing and accounting

- Improved supplier management

- Better control over stock levels and costs

- Scalable solution for growing manufacturers

Odoo allows manufacturers to track the variance between theoretical and actual material consumption in real time, providing greater accuracy and insight for decision-making.

By streamlining purchasing and accounting processes, Odoo helps businesses deliver better service to their customers through faster response times and improved reliability.

Odoo allows businesses to focus on production and innovation rather than manual administration.

Turn Data into Control

Explore Odoo modules for purchasing, accounting, and reporting

Conclusion

Raw material purchasing accounting with Odoo provides a company with a powerful, integrated solution to manage procurement, inventory, and accounting in one system. By enabling companies to plan their raw material purchasing and accounting processes, Odoo automates workflows, centralizes data, and connects purchasing directly with manufacturing and financial reporting. This helps companies improve efficiency, reduce costs, and maintain accurate accounts.

For manufacturers seeking better control over raw materials, production costs, and financial performance, Odoo ERP offers a future-ready platform that supports sustainable growth and intelligent manufacturing.

FAQs

It is the process of recording and managing all financial transactions related to purchasing raw materials used in production.

Odoo automatically generates accounting entries from validated vendor bills, reducing manual work. For example, when a purchase order is confirmed and the vendor bill is validated, Odoo creates the necessary journal entries to reflect the transaction in your accounts.

Yes, Odoo allocates landed costs such as freight and duties directly to inventory value.

Stock levels are updated automatically when materials are received, ensuring real-time accuracy.

Yes, Odoo is scalable, affordable, and designed to support SMEs as they grow.

BOMs define material requirements, while work orders track material consumption during production.

Automation and integration significantly reduce human errors across purchasing and accounting processes.