Speed alone is not enough to run efficient manufacturing operations. What truly separates efficient manufacturers from struggling ones is visibility. Knowing exactly what is happening on the shop floor, at every moment, is essential for meeting production schedules, controlling costs, and maintaining customer satisfaction.

This is where real time production monitoring with Odoo Manufacturing becomes a powerful advantage.

Many manufacturers still rely on delayed reports, spreadsheets, or manual updates to understand their production status. By the time issues appear in reports, delays, quality problems, or material shortages have already caused damage. Odoo Manufacturing changes this approach by providing real time visibility into production processes, work centers, inventory levels, and quality checks, all within a single ERP system.

The following sections explain how real time production monitoring with Odoo Manufacturing works, why it matters for modern manufacturing operations, and how it helps manufacturers achieve operational excellence.

Key Takeaways

- Real time production monitoring with Odoo Manufacturing provides live visibility into manufacturing operations

- Integrated production, inventory, quality, and maintenance data reduces communication gaps and human error

- Real-time dashboards support faster and better decision making

- Manufacturers gain better control, higher productivity, and improved customer satisfaction

- Odoo ERP offers a scalable, integrated ERP for manufacturing

Key Takeaways

What Is Real-Time Production Monitoring with Odoo Manufacturing?

Why Manufacturing Operations Need Real-Time Monitoring

Key Features of Real-Time Production Monitoring in Odoo Manufacturing

1. Live Work Center and Shop Floor Visibility

2. Production Orders and Manufacturing Process Tracking

3. Real-Time Inventory Management and Raw Materials Control

4. Integrated Quality Checks and Quality Control

5. Maintenance and Predictive Maintenance Monitoring

Real-Time Dashboards and Smarter Decision Making

Business Benefits of Real-Time Production Monitoring with Odoo

Implementation Approach for Real-Time Monitoring in Odoo

How DOODEX Supports Real-Time Production Monitoring in Odoo

Conclusion

FAQs

What Is Real-Time Production Monitoring with Odoo Manufacturing?

Odoo Manufacturing work orders planning dashboard with real-time production schedules

Real-time production monitoring with Odoo Manufacturing means tracking manufacturing orders, work orders, materials, and production data as they happen, not hours or days later. Every activity on the shop floor is recorded in the system and immediately available to production managers, supervisors, and decision makers.

With Odoo’s manufacturing module, production orders update live as operators start or finish tasks. Work centers show their current status, whether running, idle, blocked, or under maintenance. Inventory consumption is reflected instantly, ensuring that raw materials and finished products are always visible across the system.

Instead of guessing or waiting for end-of-shift reports, manufacturers gain real time insights into their manufacturing process. This level of transparency transforms production monitoring from a reactive task into a proactive management tool.

Why Manufacturing Operations Need Real-Time Monitoring

Manufacturing operations are complex, involving people, machines, materials, and schedules. Without real time visibility, small issues quickly turn into major disruptions.

Common challenges without real-time monitoring include:

- Limited visibility on the shop floor

- Communication gaps between production, inventory, and sales

- Human error from manual data entry

- Inaccurate production schedules

- Unexpected downtime and material shortages

These issues directly affect production efficiency, cost control, and customer orders. When manufacturers cannot track progress in real time, decision making is slow and often based on incomplete information.

Real time production monitoring with Odoo solves these challenges by providing up to date information across the entire manufacturing sector, helping teams respond immediately to issues and keep operations under control.

Losing Control of Production Data?

Get expert guidance to implement acurate real-time monitoring with Odoo

Key Features of Real-Time Production Monitoring in Odoo Manufacturing

1. Live Work Center and Shop Floor Visibility

Odoo provides real-time shop floor screens that display the current status of each work center. Operators can start and stop work orders, record quantities produced, and report issues directly from these interfaces.

Supervisors gain instant visibility into:

- Which production line is active

- Which work centers are overloaded

- Where bottlenecks are forming

- How much time production actually takes

This real time visibility allows managers to identify bottlenecks early and reallocate resources before delays impact delivery commitments.

2. Production Orders and Manufacturing Process Tracking

Odoo tracks manufacturing orders from start to finish. Planned production schedules are continuously compared with actual production data, highlighting delays or deviations immediately.

Manufacturers can:

- Track progress of each production order

- Compare planned vs actual time production

- Identify inefficiencies in manufacturing operations

- Adjust priorities in real time

This level of control improves overall efficiency and helps ensure that production processes remain aligned with business goals.

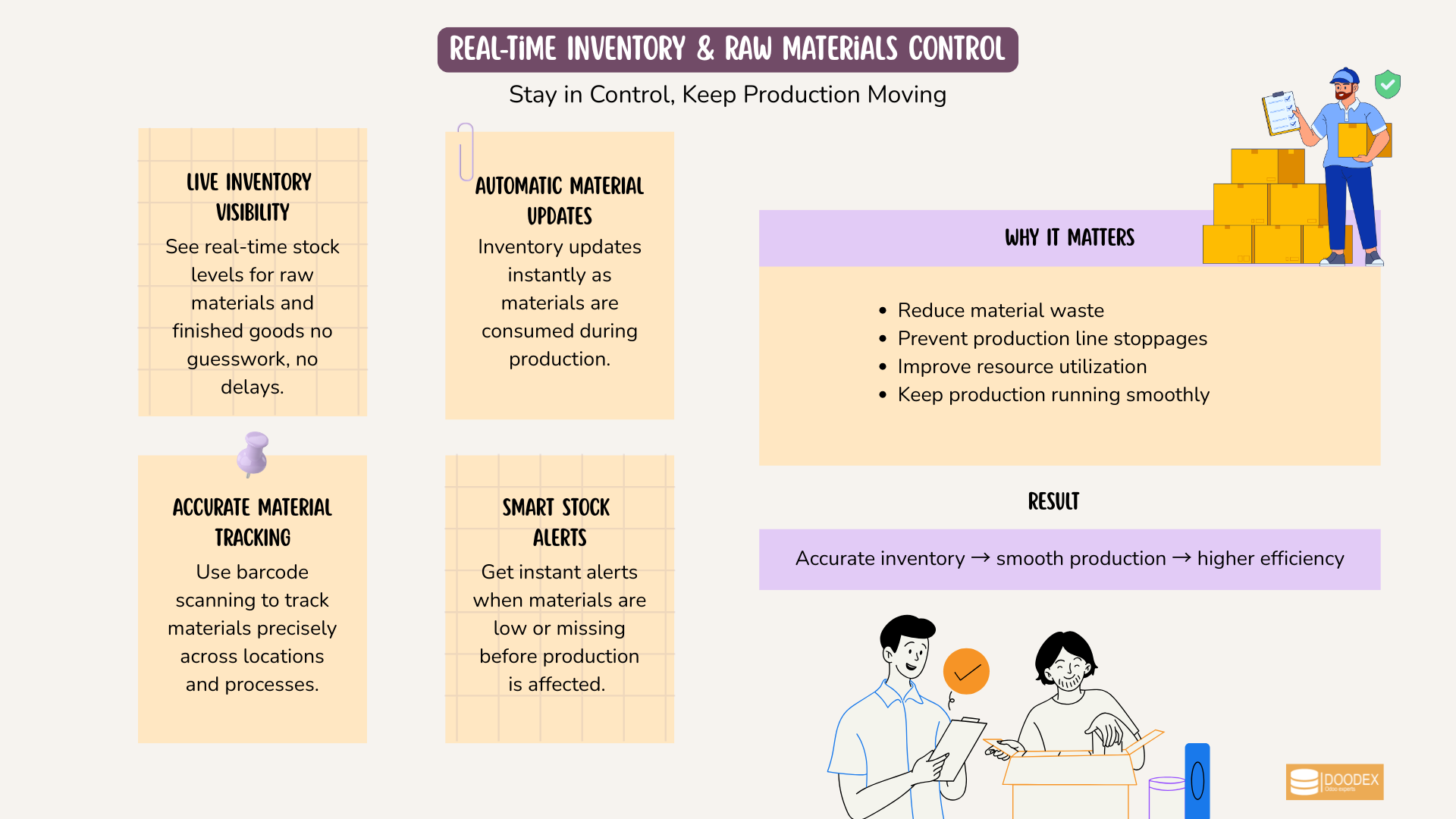

3. Real-Time Inventory Management and Raw Materials Control

Real-time inventory and raw material control in manufacturing

Production monitoring is ineffective without accurate inventory data. Odoo integrates manufacturing and inventory management seamlessly, providing real time inventory visibility.

Key capabilities include:

- Live inventory levels for raw materials and finished products

- Automatic updates as materials are consumed

- Barcode scanning for accurate material tracking

- Alerts when materials are missing or running low

By linking inventory management directly to production orders, Odoo reduces waste, prevents line stoppages, and supports better resource utilization.

4. Integrated Quality Checks and Quality Control

Quality issues often appear during production, not at the end. Odoo embeds quality checks directly into the manufacturing process, ensuring that quality control happens in real time.

Manufacturers can:

- Define quality checks at specific production stages

- Record quality results instantly

- Detect defects early

- Reduce scrap and rework

Real-time quality monitoring improves consistency, reduces waste, and protects customer satisfaction by ensuring only compliant finished products move forward.

5. Maintenance and Predictive Maintenance Monitoring

Unexpected downtime is one of the biggest threats to production efficiency. Odoo supports scheduling maintenance based on actual machine usage and production data.

With real-time monitoring, manufacturers can:

- Track machine performance and downtime

- Identify recurring issues

- Schedule maintenance proactively

- Extend equipment lifespan

Predictive maintenance reduces unexpected downtime and supports smoother manufacturing operations.

Real-Time Dashboards and Smarter Decision Making

Odoo provides powerful dashboards that consolidate production data into clear, actionable views. Managers no longer need to collect information from multiple systems or spreadsheets.

Dashboards can display:

- Production vs plan

- Work center utilization

- Inventory availability

- Quality issues

- Overall efficiency metrics

These real time insights support faster and more accurate decision making, enabling teams to maintain control over operations even as complexity grows.

✨Pro Tip

Build it right, then scale

Configure real-time monitoring for one production line or a limited set of work centers first.

Verify that time tracking, quantities, and material consumption reflect what actually happens on the shop floor.

Accurate data → trusted dashboards → scalable real-time monitoring

Business Benefits of Real-Time Production Monitoring with Odoo

Manufacturers that adopt real time production monitoring with Odoo Manufacturing typically see improvements across multiple areas:

- Higher productivity through better visibility and reduced idle time

- Improved cost control by identifying inefficiencies and waste

- Reduced downtime through proactive maintenance

- Better production efficiency with optimized resource utilization

- Increased customer satisfaction due to reliable delivery and quality

By streamlining operations and reducing errors, Odoo becomes a comprehensive solution for manufacturers seeking operational excellence.

Implementation Approach for Real-Time Monitoring in Odoo

Implementing real-time production monitoring does not require a complete system overhaul from day one. Successful projects usually follow a phased approach:

- Discovery and production planning to map current manufacturing processes

- Configuration of the manufacturing module and work centers

- Pilot implementation on selected production lines

- Gradual rollout and optimization with ongoing support

This approach allows growing businesses to adopt real-time monitoring with minimal risk while delivering measurable value early.

How DOODEX Supports Real-Time Production Monitoring in Odoo

Configuring real-time production monitoring in Odoo is not only a technical task. It is a process design challenge that requires a deep understanding of manufacturing operations, shop-floor realities, and how data should flow between production, inventory, quality, and maintenance.

This is where working directly with an official Odoo partner becomes valuable.

As an experienced Odoo implementation partner, DOODEX focuses on aligning Odoo Manufacturing with real production behavior, not forcing generic ERP workflows onto the factory floor. Instead of overloading teams with complex setups from day one, DOODEX helps manufacturers define what “real-time” truly means for their operations and implement it in a practical, phased way.

Manufacturers choose to work with DOODEX because:

- Production monitoring is designed around actual work centers and production lines, not assumptions

- Dashboards and KPIs reflect operational reality, not theoretical metrics

- Inventory, quality, and maintenance flows are connected from the start, reducing rework later

- Teams receive clear guidance and ongoing support, ensuring adoption beyond go-live

By collaborating directly with an official Odoo partner, manufacturers reduce implementation risk, avoid costly redesigns, and reach operational excellence faster. The result is not just a working system, but a real-time production monitoring setup that teams trust and use every day.

Ready for Real-Time Manufacturing?

Learn how Doodex helps manufacturing build real-time production monitoring with Odoo

Conclusion

Real-time production monitoring with Odoo Manufacturing transforms how manufacturers manage their operations. By replacing delayed reports and fragmented systems with real time data, manufacturers gain control, reduce waste, and improve efficiency across the entire manufacturing process.

For manufacturers looking to streamline operations, improve decision making, and achieve sustainable growth, Odoo ERP stands out as a powerful and flexible ERP for manufacturing. Real time visibility is no longer optional. It is a critical foundation for modern manufacturing success.

FAQs

It is the ability to track production orders, work orders, inventory, and quality checks as they happen within Odoo’s manufacturing module.

Yes. Operators can input data directly on shop floor screens. IoT integration is optional and can be added later.

It identifies bottlenecks, reduces downtime, improves scheduling, and supports faster decision making.

Yes. Odoo’s modular structure makes it suitable for both small manufacturers and complex operations.

By providing real-time visibility into quality issues, material usage, and inefficiencies.

Yes. Odoo supports multiple work centers, production lines, and even multi-site manufacturing.

A basic setup can be achieved in weeks, with continuous improvements added over time.